How to recognize the ultrafilter membrane(1)

Author: infinipure

Release time: 2025-12-24 01:31:29

View number: 174

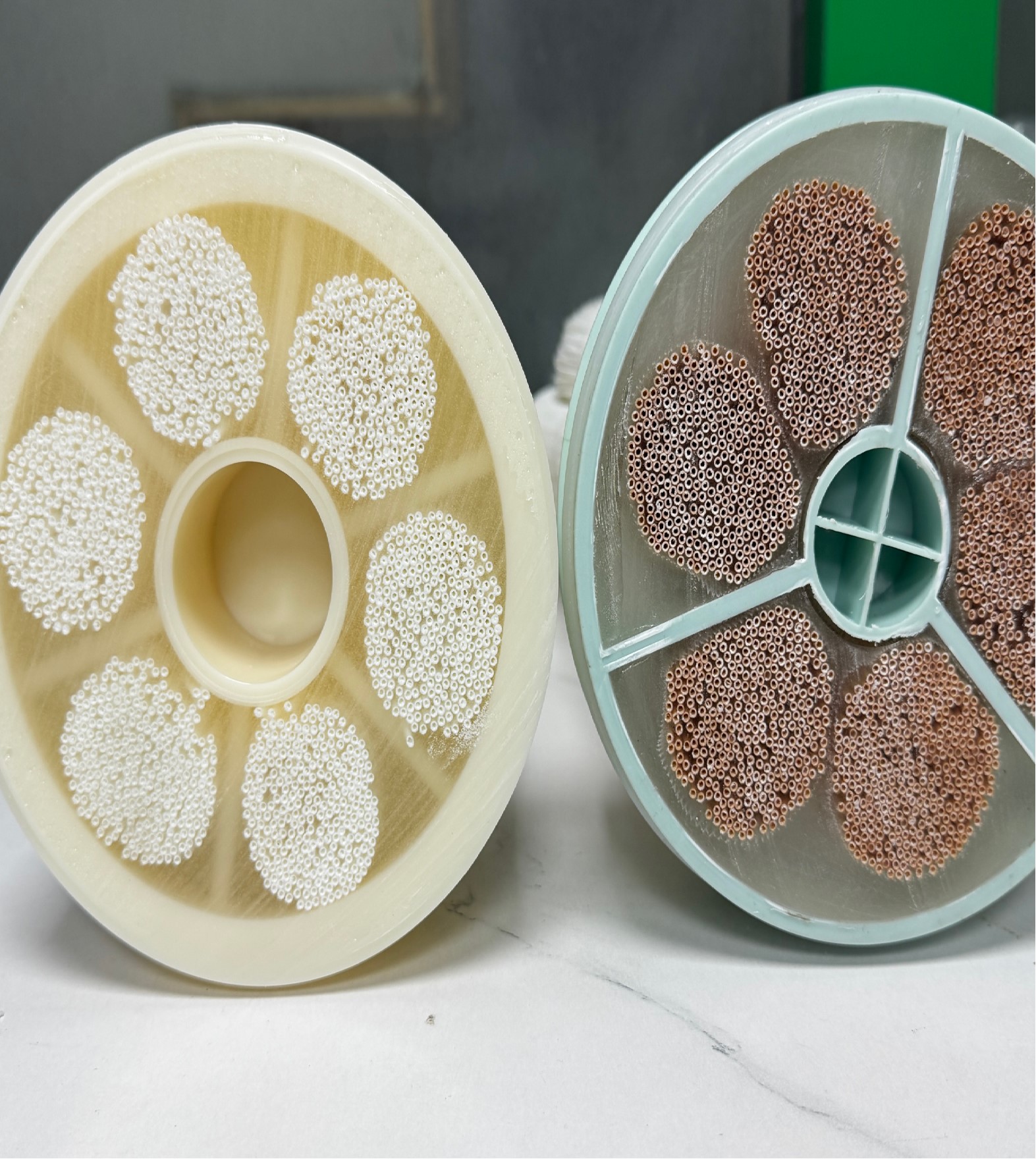

A brand-new, qualified filter cartridge should have completely clean filter media (ultrafiltration membrane) and end caps upon leaving the factory. The membrane fibers should be naturally white at the base, the O-rings should be uniform and clean, and there should be no retained contaminants. If the end face of an unused filter cartridge is reddish-brown, in extreme cases, it may indicate the use of contaminated membrane fiber raw materials or non-new components. Besides problems with the membrane fiber raw materials, epoxy resin adhesive is also a very important and common reason for the reddish discoloration of the membrane fibers at the end of a new filter cartridge. Most epoxy resins used to bond the filter cartridge end caps are two-component (resin + hardener). Commonly used amine-based hardeners (such as polyamides and aliphatic amines), after curing, will slowly oxidize when exposed to air (especially humid air). These oxidized amine compounds will produce a series of complex quinone structures or azo compound byproducts. The color of these chemicals is yellow, red, or brown. This process is similar to how a cut apple turns brown after being left out for a while. This reddish-brown color affects the product's appearance and the sensory experience during initial use (the first few cups of water may have an unpleasant taste). Low-quality adhesives not only cause color problems, but their non-food-grade raw materials may release unknown chemicals, posing a potential risk to drinking water safety. Good adhesives should prioritize the use of high-quality, antioxidant, food-grade adhesives. High-end filter cartridges use polyurethane adhesives or modified epoxy resin adhesives, which contain antioxidants and UV stabilizers to slow down or prevent the yellowing and aging of the adhesive.

The membrane fibers penetrated and cured by the adhesive become brittle and lose flexibility. Adding a layer of soft polyurethane adhesive on top of the hard structural adhesive (such as epoxy resin) can significantly improve the resistance of the membrane fiber base to damage during manual cleaning, significantly improving the mechanical lifespan of the filter cartridge (especially for hand-washable types).